The Honeywell T10 Thermostat is a smart, user-friendly device designed for effortless temperature control. It offers compatibility with smart home systems and features a sleek touchscreen interface. The thermostat is ideal for managing heating and cooling systems efficiently, providing precise comfort and energy savings. With its advanced programming capabilities and integration with the Honeywell Home app, it simplifies home climate control. Perfect for modern homes, the T10 balances convenience and performance seamlessly.

1.1 Key Features and Benefits

The Honeywell T10 Thermostat offers a 7-day scheduling feature, allowing users to customize their comfort settings throughout the week. It supports geofencing and smart sensors for enhanced temperature control. Compatibility with smart home systems like Amazon Alexa and Google Home enables voice commands and seamless integration. The thermostat also provides energy-saving features by learning and adapting to usage patterns. Its touchscreen interface ensures easy navigation, while remote access via the Honeywell Home app offers convenience. These features make the T10 a versatile and efficient choice for modern home climate management.

1.2 Compatibility with Smart Home Systems

The Honeywell T10 Thermostat seamlessly integrates with popular smart home systems such as Amazon Alexa and Google Home. This compatibility allows users to control their thermostat with voice commands, enhancing convenience. Additionally, the T10 works with RedLINK 3.0 technology, ensuring reliable communication with other Honeywell devices. Its integration with the Honeywell Home app enables remote temperature adjustments and scheduling. This feature-rich compatibility ensures the T10 fits effortlessly into any smart home ecosystem, offering a unified system for optimal comfort and energy efficiency.

Installation Guide

The Honeywell T10 Thermostat is designed for compatibility with 24 VAC systems, ensuring easy installation. Mount the thermostat, connect wires, and set up via the Honeywell Home app for seamless control.

2.1 Compatibility Check for HVAC Systems

Before installing the Honeywell T10 Thermostat, ensure your HVAC system is compatible. The T10 works with 24 VAC heating and cooling systems, including conventional and heat pump setups. Verify compatibility by checking your system’s voltage and configuration. Proper installation requires a C-wire for consistent power supply. If unsure, consult a professional or refer to the system’s manual. Compatibility ensures optimal performance and avoids electrical hazards.

2.2 Step-by-Step Installation Process

- Turn off power to your HVAC system at the circuit breaker.

- Open the thermostat package and position the UWP on the wall.

- Pull the door open and insert wires through the wiring hole.

- Mount the thermostat and connect wires to the appropriate terminals.

- Turn the power back on and configure settings via the touchscreen.

Programming the Honeywell T10 Thermostat

The Honeywell T10 Thermostat offers straightforward programming with a 7-day schedule and advanced features like geofencing and smart sensors for optimized comfort and energy efficiency.

3.1 Setting Up a 7-Day Schedule

To set up a 7-day schedule on the Honeywell T10 Thermostat, access the menu and select “Create New Schedule.” Choose the days you want to program and configure the temperature settings for each period. Save your preferences to apply the schedule. The thermostat allows you to customize temperatures for different times of the day, ensuring optimal comfort and energy efficiency. Use the Honeywell Home app for remote adjustments and enable features like geofencing to automatically adjust settings based on your location.

3.2 Advanced Features: Geofencing and Smart Sensors

The Honeywell T10 Thermostat offers advanced features like geofencing, which adjusts temperatures based on your location, and smart sensors that detect temperature and humidity. Geofencing automatically switches to energy-saving modes when you leave home and resumes comfort settings upon your return. Smart sensors optimize heating and cooling by monitoring conditions in different rooms, ensuring balanced comfort. These features integrate seamlessly with the Honeywell Home app, allowing remote control and customization for enhanced efficiency and convenience.

Manual Operation and Adjustments

The Honeywell T10 Thermostat allows manual temperature adjustments, enabling users to override scheduled settings. You can disable the schedule for temporary or permanent manual control, ensuring flexibility in temperature management.

4.1 Adjusting Temperature Manually

The Honeywell T10 Thermostat allows users to manually adjust the temperature with ease. Simply tap the touchscreen to increase or decrease the setpoint. You can override the schedule temporarily or permanently by selecting the “Hold” option. This feature is useful for unexpected changes in your routine. Additionally, the Honeywell Home app enables remote manual adjustments, ensuring you can control your home’s temperature from anywhere. Manual adjustments provide flexibility, allowing you to customize comfort without altering the programmed schedule.

4.2 Disabling the Schedule for Manual Control

To disable the schedule and switch to manual control, navigate to the menu and select the “Disable Schedule” option. This allows you to adjust the temperature without following the programmed settings. Manual control provides flexibility for temporary changes. You can override the schedule permanently or until the next scheduled period. Use the touchscreen or the Honeywell Home app to make adjustments. This feature is ideal for days when your routine changes unexpectedly. Once disabled, the thermostat will maintain the manual temperature until you re-enable the schedule or set a new one.

Maintenance and Troubleshooting

Regularly clean the thermostat display and sensors for optimal performance. Check for firmware updates via the Honeywell Home app. Troubleshoot issues like connectivity problems or sensor malfunctions.

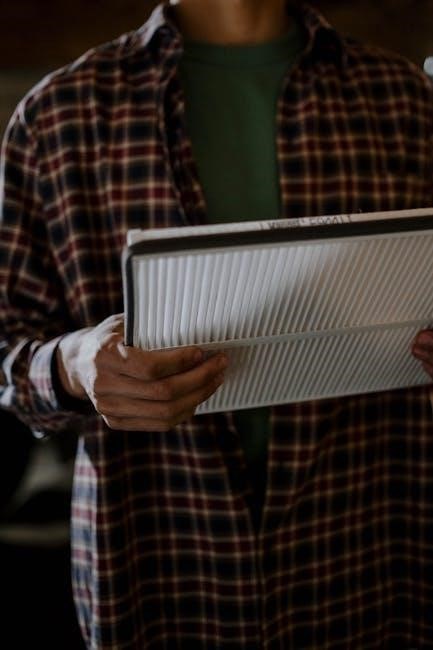

5.1 Cleaning and Upkeeping the Thermostat

Regular maintenance ensures the Honeywell T10 Thermostat operates efficiently. Clean the display and sensors with a soft, dry cloth to remove dust and debris. Avoid harsh chemicals or liquids, as they may damage the components. Check the device for firmware updates through the Honeywell Home app to ensure optimal functionality. For stubborn stains, lightly dampen the cloth with water, but avoid moisture entering the thermostat. Schedule periodic cleaning to maintain accuracy and responsiveness. Proper upkeep extends the lifespan and performance of your Honeywell T10 Thermostat.

5.2 Common Issues and Solutions

Common issues with the Honeywell T10 Thermostat include error codes like W012 (excessive offset) and connectivity problems. For W012, check temperature settings or reset the device. Firmware updates may resolve software-related issues; use a USB flash drive to install updates. If sensors malfunction, ensure they are properly connected and positioned. For electrical issues, inspect wiring connections and restart the thermostat. Refer to the Honeywell Home app or user manual for troubleshooting guides. Regularly updating firmware and ensuring proper installation can prevent many of these issues, ensuring smooth operation.

Integration with Smart Home Systems

The Honeywell T10 Thermostat seamlessly integrates with Amazon Alexa and Google Home, enabling voice control and smart home automation. Use the Honeywell Home app for remote control and system management.

6.1 Compatibility with Amazon Alexa and Google Home

The Honeywell T10 Thermostat is fully compatible with Amazon Alexa and Google Home, allowing seamless voice control for temperature adjustments. Users can enable voice commands to change settings effortlessly. The Honeywell Home app ensures smooth integration, enabling remote management of your smart thermostat. This compatibility enhances smart home automation, providing a convenient and efficient way to control your home’s climate. With just a few voice commands, you can adjust temperatures, set schedules, or even disable the current schedule for manual control, making it a versatile addition to any smart home system.

6.2 Security Tips for Smart Thermostat Integration

Ensure your Honeywell T10 Thermostat integration is secure by enabling two-factor authentication for your Honeywell Home app account. Regularly update the thermostat’s firmware to protect against vulnerabilities. Use strong, unique passwords for your Wi-Fi network and smart home devices. Avoid using public networks for thermostat control and consider segregating smart devices on a dedicated network. Monitor your thermostat for unauthorized access and enable notifications for suspicious activities. This enhances your smart home security and maintains your system’s integrity.

The Honeywell T10 Thermostat is an excellent choice for smart home solutions, offering energy efficiency and seamless integration. Regular updates and adjustments ensure optimal performance and comfort.

7.1 Summary of Key Features and Benefits

The Honeywell T10 Thermostat offers a 7-day programmable schedule, geofencing, and smart sensor integration for precise temperature control. It is compatible with most HVAC systems and smart home platforms like Amazon Alexa and Google Home. Energy efficiency and a user-friendly interface make it a top choice for modern homes. The thermostat also supports manual adjustments and scheduling disablement for flexibility. Its advanced features ensure comfort and energy savings, while regular updates and maintenance tips from the Honeywell Home app enhance performance and longevity.

7.2 Final Tips for Optimal Performance

For optimal performance, regularly clean the thermostat and ensure proper sensor functionality. Update firmware via USB or the Honeywell Home app for the latest features. Always check compatibility with your HVAC system before installation. Use geofencing and smart sensors to maximize energy efficiency. Disable schedules when not needed for manual control. Refer to the Honeywell T10 manual for troubleshooting common issues and maintaining settings. Proper maintenance ensures long-term reliability and enhances comfort.