Venkateswara Ashtothram Telugu PDF: An Overview

This sacred collection presents the 108 divine names of Lord Venkateswara in Telugu. It serves as an essential guide for devotees seeking a profound connection with the divine, offering a path to receive blessings and attain spiritual grace through devout chanting. Easily accessible for spiritual practice.

Defining Venkateswara Ashtothram

The Venkateswara Ashtothram, also widely known as Venkateswara Ashtottara Shatanamavali, is a revered compilation of 108 sacred names dedicated to Lord Venkateswara. Specifically, it refers to the divine names of Lord Venkateswara of Tirumala, presented in the eloquent Telugu language and script. This special collection serves as a foundational text for devotees, offering a structured way to invoke and meditate upon the multifaceted aspects of the deity. The term ‘Ashtothram’ itself signifies ‘108 names,’ a number profoundly significant in Hindu spiritual practices, symbolizing completeness and spiritual potency. When accessed in Telugu PDF format, it provides an authentic and convenient resource for individuals to engage in devotional chanting. This practice is central to fostering a deeper spiritual connection, allowing adherents to express their reverence and seek the grace of the Lord. The Ashtothram is more than just a list of names; it is a devotional hymn encapsulating the Lord’s attributes, glories, and epithets, making it a powerful tool for worship and contemplation. Its availability in digital formats like PDF ensures widespread access for spiritual enrichment across the globe, facilitating daily prayers and special observances with ease.

The Significance of 108 Names

The 108 names within the Venkateswara Ashtothram carry profound spiritual weight, a number deeply revered in Hindu tradition. This count, 108, symbolizes completeness and divine expression. In the context of the Venkateswara Ashtottara Shatanamavali, each name reveals a unique attribute, glory, or epithet of Lord Venkateswara of Tirumala. Chanting these distinct names allows devotees to connect with various divine aspects, fostering a deep understanding of His multifaceted nature. This practice is highly auspicious and powerful, echoing traditional malas, which feature 108 beads for mantra recitation. The number 108 is also significant in ancient Indian cosmology, derived from multiplying 12 zodiac signs by 9 planets (12×9=108), or 27 lunar mansions (nakshatras) each with 4 quarters (27×4=108). Therefore, engaging with the Venkateswara Ashtothram’s 108 names in Telugu is more than simple devotion; it is a holistic spiritual exercise. It aligns the chanter with universal divine energy, invoking the full spectrum of Lord Venkateswara’s blessings and grace. This sacred enumeration is believed to purify the mind, elevate consciousness, and strengthen one’s bond with the supreme deity, making it a truly vital and indispensable part of devotional practice.

Purpose: Connecting with the Divine

The Venkateswara Ashtothram Telugu PDF serves a singular, profound purpose: fostering a deep connection with Lord Venkateswara. It is ideal for anyone seeking to truly connect with the divine. By reciting the 108 sacred names, devotees engage in a powerful spiritual practice, bridging material and divine realms. This is not just a ritual; it’s a heartfelt act of surrender and adoration, focusing intently on the Lord’s glorious attributes. Chanting these names in Telugu creates a resonant spiritual atmosphere, inviting divine presence. It purifies the mind, calms anxieties, and fosters inner peace. Through dedicated practice, devotees transcend worldly distractions, immersing themselves in the Supreme Being’s contemplation. This engagement cultivates unwavering faith and love, leading to an intimate relationship with Lord Venkateswara. It offers a direct pathway to experience His grace and receive blessings, transforming the spiritual journey into profound personal divine communion.

Core Content: The 108 Names

This core section presents the Venkateswara Ashtottara Shatanamavali, the revered 108 names of Lord Venkateswara of Tirumala. This special Telugu collection offers devotees a profound means to connect with the divine, forming the heart of the Ashtothram’s spiritual practice and devotion.

Lord Venkateswara of Tirumala

Lord Venkateswara, the revered deity of the sacred Tirumala Venkateswara Temple, stands as a beacon of devotion for millions worldwide. Situated in the picturesque Seshachalam hills of Andhra Pradesh, this ancient shrine is among the most visited holy sites, drawing devotees who seek spiritual solace and divine blessings. Known by various names such as Balaji, Srinivasa, and Govinda, Lord Venkateswara is believed to be a manifestation of Vishnu, who descended to Earth to guide and protect humanity during the present Kali Yuga. His divine presence at Tirumala is considered extraordinarily potent, capable of fulfilling the prayers and aspirations of his sincere worshippers. The spiritual ambiance of the temple complex and the captivating idol of the Lord inspire profound reverence and unwavering faith. Pilgrims undertake dedicated journeys to experience the sacred darshan (sight) of the deity, believing it bestows immense spiritual merit and purifies the soul. The worship of Lord Venkateswara is deeply rooted in centuries of tradition, making Tirumala a paramount spiritual destination.

Venkateswara Ashtottara Shatanamavali

The Venkateswara Ashtottara Shatanamavali, often simply referred to as Venkateswara Ashtothram, is a profound and sacred compilation comprising 108 distinct names of Lord Venkateswara of Tirumala. This revered set of names is a cornerstone of devotional practice for countless adherents, offering a structured and heartfelt way to connect with the divine presence of the deity. Each name within the Ashtottara Shatanamavali encapsulates a unique attribute, quality, or divine manifestation of Lord Venkateswara, allowing devotees to meditate upon his multifaceted glory. Chanting these 108 names with sincerity and devotion is believed to be immensely beneficial, leading to the attainment of divine grace and the blessings of the Lord. The Telugu rendition of this powerful stotram is widely sought after, providing an accessible means for Telugu-speaking devotees to engage in this profound spiritual exercise. Many resources make the Sri Venkateswara Ashtothram in Telugu lyrics available in PDF format, enabling easy access for chanting and personal reflection. This collection serves as a direct conduit for expressing reverence and fostering a deeper spiritual bond with the divine.

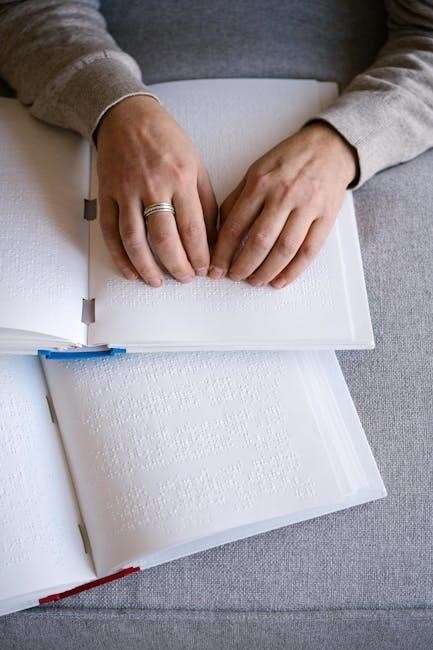

Example Names in Telugu Script

Within the sacred Venkateswara Ashtothram, each of the 108 names is presented in the beautiful Telugu script, offering devotees a direct visual and phonetic connection to the divine. These names are not merely appellations but profound invocations, each signifying a unique attribute or form of Lord Venkateswara. For instance, the Ashtothram typically begins with “ఓ వేకటేశాయ నమ” (Om Venkateshaya Namaha), revering the Lord as Venkateswara himself. Another significant name is “ఓ ్ర నివాసాయ నమ” (Om Srinivasaya Namaha), which translates to the abode of Sri (Goddess Lakshmi), highlighting his consort. Further examples include “ఓ ల్మ పతయే నమ” (Om Lakshmi Pataye Namaha), signifying him as the husband of Lakshmi, and “ఓ గోవిదాయ నమ” (Om Govindaya Namaha), a widely recognized and cherished name of Vishnu. Other names like “ఓ అనామయాయ నమ” (Om Anamayaya Namaha), meaning one without affliction, “ఓ అమతాశాయ నమ” (Om Amrutashaya Namaha), one who desires immortality, “ఓ జగద్వదా్యయ నమ” (Om Jagadvandyaya Namaha), one worshipped by the universe, and “ఓ శాశ్వతాయ నమ” (Om Shashvataya Namaha), the eternal one, provide a glimpse into the diverse qualities attributed to the deity. These specific examples, written in Telugu script, allow practitioners to engage deeply with the spiritual essence of each invocation, fostering a rich devotional experience during chanting.

Benefits of Chanting

Chanting these sacred names brings significant spiritual rewards. Devotees receive Lord Venkateswara’s blessings, attain divine grace, and cultivate profound devotion. This practice fosters a deep connection, enriching spiritual journeys and bringing inner peace.

Receiving Lord Venkateswara’s Blessings

Chanting the Venkateswara Ashtothram is a profound spiritual practice specifically aimed at invoking and receiving the benevolent blessings of Lord Venkateswara. Devotees engaging in this sacred recitation, particularly with deep devotion and sincerity, are believed to attract the divine grace and protection of the presiding deity of Tirumala. The 108 names, each a unique attribute or manifestation of the Lord, act as powerful conduits for spiritual energy. Through consistent and heartfelt chanting, individuals can experience a tangible sense of divine presence, fostering a connection that transcends the material world. These blessings are not merely confined to spiritual well-being but are also believed to extend into various aspects of life, offering solace, guidance, and prosperity. Many believe that regular chanting can alleviate difficulties, fulfill righteous desires, and bring harmony into one’s existence, making the Ashtothram a potent tool for spiritual upliftment and receiving the Lord’s boundless compassion. The act of reciting these names in Telugu further enhances the authenticity and traditional connection for many adherents, linking them directly to centuries of devotional practice.

Attaining Divine Grace

Chanting the Venkateswara Ashtothram is a profound spiritual endeavor aimed directly at attaining the divine grace of Lord Venkateswara. This sacred practice, encompassing the 108 glorious names of the deity, serves as a powerful means for devotees to purify their minds and souls, thereby making them receptive to the Lord’s boundless compassion and blessings. Divine grace, in this context, refers to the unmerited favor and spiritual assistance bestowed by the divine, leading to inner peace, spiritual growth, and liberation from worldly attachments. By reciting the Sri Venkateswara Ashtottara Shatanamavali in Telugu with unwavering devotion, individuals are believed to forge a deep, personal connection with the supreme being. This connection facilitates the influx of positive energy, wisdom, and strength, helping adherents navigate life’s challenges with greater resilience and faith. Attaining divine grace through this Ashtothram is not merely about receiving material benefits; it is primarily about achieving spiritual enlightenment, fostering a sense of profound devotion, and experiencing an elevated state of consciousness. The consistent practice of chanting transforms the devotee, guiding them towards a more virtuous and spiritually enriched life, imbued with the Lord’s benevolent presence and guiding light. It is a path to ultimate spiritual fulfillment and harmony.

Fostering Deep Devotion

The Venkateswara Ashtothram serves as a profound tool for cultivating and deepening devotion towards Lord Venkateswara. Through the repetitive and heartfelt chanting of the 108 sacred names, devotees engage in a spiritual practice that transcends mere ritual. Each name, imbued with specific attributes and glories of the Lord, acts as a meditative point, allowing the mind to focus intensely on the divine form and virtues of Venkateswara of Tirumala. This sustained contemplation naturally leads to an increased sense of reverence, love, and surrender. The act of reciting the Sri Venkateswara Ashtottara Shatanamavali in Telugu, often from a readily available PDF, transforms an ordinary space into a sacred one, fostering an environment conducive to spiritual introspection. As one articulates each name, the heart opens, and a profound emotional connection with the deity is established. This consistent engagement helps in dissolving distractions and worldly anxieties, centering the devotee’s consciousness on the divine presence. Over time, this practice solidifies faith, transforming it from a theoretical belief into a deeply felt, personal experience. It fosters an unwavering bond with the divine, thereby leading to an enduring and profound devotion.

Accessing the Telugu PDF

Accessing the Venkateswara Ashtothram Telugu PDF is straightforward, as it’s widely available for free download. Devotees can easily find this sacred prayer in various digital formats from trusted spiritual websites. Specific sources like Stotranidhicom and RevealWall provide the complete Telugu version for devoted chanting.

Free Download Availability

The availability of this revered Telugu PDF devotional text is extensive across the internet, making it highly accessible for spiritual seekers. Devotees can readily obtain the complete Venkateswara Ashtothram, featuring the 108 sacred names, through various digital platforms. Numerous spiritual and religious websites offer this cherished compilation in a downloadable PDF format without any cost, ensuring the divine verses are within reach for anyone wishing to engage in daily worship or special devotional practices. These free downloads often provide the full lyrics, enabling users to print or view the Ashtothram conveniently on their devices. This ease of access significantly facilitates a deeper connection with Lord Venkateswara, allowing individuals to seamlessly incorporate this powerful chant into their spiritual routine. The widespread distribution underscores the communal effort to spread divine knowledge and foster devotion among the faithful. This exceptional accessibility ensures that geographical or financial barriers do not hinder one’s ability to partake in this significant spiritual practice, promoting universal participation in chanting the Lord’s glorious names. The convenience of a free download caters perfectly to the modern devotee, blending ancient tradition with contemporary technology for spiritual enrichment.

Trusted Sources for PDF

When seeking the Venkateswara Ashtothram Telugu PDF, identifying trusted sources is paramount to ensure the authenticity and accuracy of this sacred text. Reputable platforms are dedicated to preserving and disseminating devotional literature, offering reliable downloads for practitioners worldwide. Among the most recognized and frequently cited trusted sources is stotranidhicom, a well-established website known for its extensive collection of Hindu stotras and spiritual texts in various Indian languages, including Telugu. This site is a primary destination for devotees seeking accurate renditions of ancient prayers, ensuring textual integrity for worship.

Another highly recommended platform explicitly mentioned for providing the complete Telugu version of this sacred prayer is RevealWall. This source specifically caters to the availability of the Venkateswara Ashtothram in a convenient PDF format for free download; Beyond these specific examples, many other spiritual websites specializing in devotional content and religious scriptures also serve as dependable repositories. These platforms are often curated by organizations dedicated to dharma, ensuring the integrity of the texts. Choosing such sources guarantees devotees are chanting the correct and traditional names, fostering a pure and meaningful connection with Lord Venkateswara without textual discrepancies, vital for an undisturbed spiritual practice.

Digital Formats Beyond PDF

The Venkateswara Ashtothram in Telugu is not exclusively confined to PDF documents, showcasing its broad accessibility across various digital platforms. While PDF is popular for its fixed layout and print-readiness, devotees can also find this sacred chant in other convenient formats catering to diverse preferences and devices. For example, the Ashtothram is frequently available as a Word Doc (.doc / .docx). This format provides flexibility for users who may wish to customize the text, adjust font sizes, or incorporate it into their personal devotional collections. Similarly, plain Text Files (.txt) offer a minimalist and universally compatible option, easily readable on almost any device or operating system without specific software, making it ideal for quick access and basic viewing. Beyond downloadable files, numerous spiritual websites and online portals present the Ashtothram lyrics directly on their pages, facilitating online reading without any download. This functionality is perfect for immediate reference or quick recitation, especially for those preferring not to download files. Such online versions are often integrated with other devotional content, enriching the spiritual experience. These diverse digital formats ensure the Venkateswara Ashtothram remains readily available and adaptable to modern devotional practices, extending its reach beyond traditional printed or PDF versions.

Specific Websites: Stotranidhicom and RevealWall

For devotees seeking reliable access to the Venkateswara Ashtothram in Telugu PDF, several dedicated online platforms stand out as trusted sources. Among these, Stotranidhicom is frequently cited as a go-to destination for a wide array of spiritual and devotional literature. This website offers the Telugu version of the Venkateswara Ashtothram, making it readily available for free download. Its reputation stems from providing authentic and well-formatted spiritual texts, ensuring devotees receive accurate renditions for their daily prayers and rituals. Users can confidently navigate Stotranidhicom to obtain the sacred 108 names of Lord Venkateswara, often alongside other valuable stotras and devotional content.

Another prominent platform providing the Venkateswara Ashtothram in Telugu PDF is RevealWall. This site specifically highlights its offering of the complete Telugu version of this sacred prayer, emphasizing its commitment to making such vital devotional resources accessible. RevealWall ensures that the PDF is available for free download, enabling widespread participation in chanting and devotion to Lord Venkateswara. Both Stotranidhicom and RevealWall play crucial roles in disseminating these invaluable spiritual texts, facilitating easy access for the global Telugu-speaking devotional community and beyond, ensuring the tradition of chanting continues to thrive in the digital age.

Chanting Guidelines and Practice

For effective chanting of Venkateswara Ashtothram, profound devotion is key. Uttering the 108 sacred names with a pure heart fosters deep connection with the divine. This practice ensures devotees receive Lord Venkateswara’s blessings, enhancing spiritual grace and faith.

Importance of Devotion in Chanting

Devotion is the very essence of chanting Venkateswara Ashtothram. It transcends simple vocalization, elevating practice from mere ritual to profound spiritual communion. When devotees chant with deep devotion, their hearts and minds align with the sacred 108 names of Lord Venkateswara, transforming each utterance into a powerful prayer. This heartfelt sincerity is crucial for invoking the Lord’s blessings and experiencing profound divine grace. Without genuine devotion, recitation, though acoustically correct, lacks spiritual energy and deep connection—the Ashtothram’s true purpose. Fervent belief, unwavering faith, and pure love embedded in each sacred name effectively open spiritual channels, allowing chanters to absorb and internalize divine vibrations. This internal dedication ensures the devotee actively engages in meaningful dialogue with the divine presence, not just reciting mechanically. It cultivates deep surrender, humility, and unwavering faith, foundational for spiritual growth and inner peace. The profound heart commitment enriches the entire chanting experience, making it a transformative, deeply personal journey. Thus, effectiveness and spiritual rewards of chanting Venkateswara Ashtothram are inextricably linked to devotion’s depth and purity of intent. It is the key to unlocking this sacred practice’s full potential, fostering an intimate, blessed relationship with the deity.

Related Devotional Literature

Beyond Venkateswara Ashtothram, a rich array of devotional literature exists. This includes numerous other Ashtothrams in Telugu PDF format, such as those dedicated to Lakshmi, Shiva, Subrahmanya, Ganesha, and Durga. These sacred texts offer diverse paths for spiritual connection and divine worship.

Other Ashtothrams in Telugu PDF

Beyond the revered Venkateswara Ashtothram, a vast and spiritually enriching collection of other Ashtothrams is readily available in Telugu PDF format, catering to devotees of various deities. These sacred texts, each comprising 108 names, offer a profound means to connect with specific aspects of the divine. For instance, the Shiva Ashtottara Shatanamavali provides a detailed invocation of Lord Shiva, allowing practitioners to immerse themselves in his divine attributes. Similarly, the Lakshmi Ashtothram is vital for those seeking the blessings of Goddess Lakshmi, embodying prosperity and grace. Devotees can also find Ashtothrams dedicated to other prominent deities, such as Subrahmanya, Ganesha, Durga, and Vishnu. The Kamakshi-Ashtottara-shatanamavali and Krishna Ashtottara Shatanama Stotram are also widely sought after, providing unique devotional experiences. These PDFs are invaluable resources, enabling individuals to perform daily prayers, participate in special poojas, and deepen their spiritual practice from the comfort of their homes. Accessing these diverse Ashtothrams facilitates a comprehensive devotional journey, fostering immense faith and receiving varied divine graces, strengthening one’s spiritual foundation.